Types of Packed Column. A complete line of plastic packed tower internalsThis has been achieved by 20 years of testing and supplying INTALOX Distribution Systems.

Packed Column Internals Ppt Video Online Download

900 mm Used for large diameter.

. The Uses of Packed Columns. A packed columns performance often relies on the proper distribution of gas and liquid in the packed bed. E Approximate designs are required for pre-sanction flowsheeting where cost estimating is the main requirement.

F Detailed designs are required for. If your column is a welded. By understanding the important role of liq- uid and vapor distribution Koch-Glitsch.

Index Column Internals The Importance of Internals in Packed Columns 1 The Influence of Internals on Mass Transfer Efficiency 2-9 Support Plates in Metal and Plastic 10 Multibeam Support Plate Type SP1 11-13 Multibeam Support Plate Type SP2 and SP3 14-16 Hexa-Grid Support Plate Type SP-HG 17-18 Cross-Flow-Grid Support Plate Type SP-CF 19-20. Packed Columns play an important role in distillation absorption and stripping processesThis brouchure provides the information of the key design and specification of column packings. Saint-Gobain NorPro confidently designs internals for any size tower from the beginning without the need to test each internal before shipping although such testing is available on request.

EIGHT PRACTICAL STEPS 1. Internals for packed columns 3 0600 2508-2 0600 2508-4. INTALOX Packed Tower Systems combine INTALOX liquid.

Our principal focus is on improving products quality and customer satisfaction. A Random Packed Column b Grid. Column type When preparing column internals specifications you must know whether you will be using a flanged column or a welded vessel.

With this column we study the effects of various liquid and vapor flow rates. Select a process control scheme. As such a packed bed columns design needs to take this proper distribution into account.

By understanding the important role that liquid and vapor distri-bution playsKoch-Glitsch can design packed columns to deliver predictable performance. 141 the reflux ratio is given by r r-n TTTT 14-18 The molar flow rate at the head of the column would then be V F XFXB. Hydraulic simulation column at our research facility.

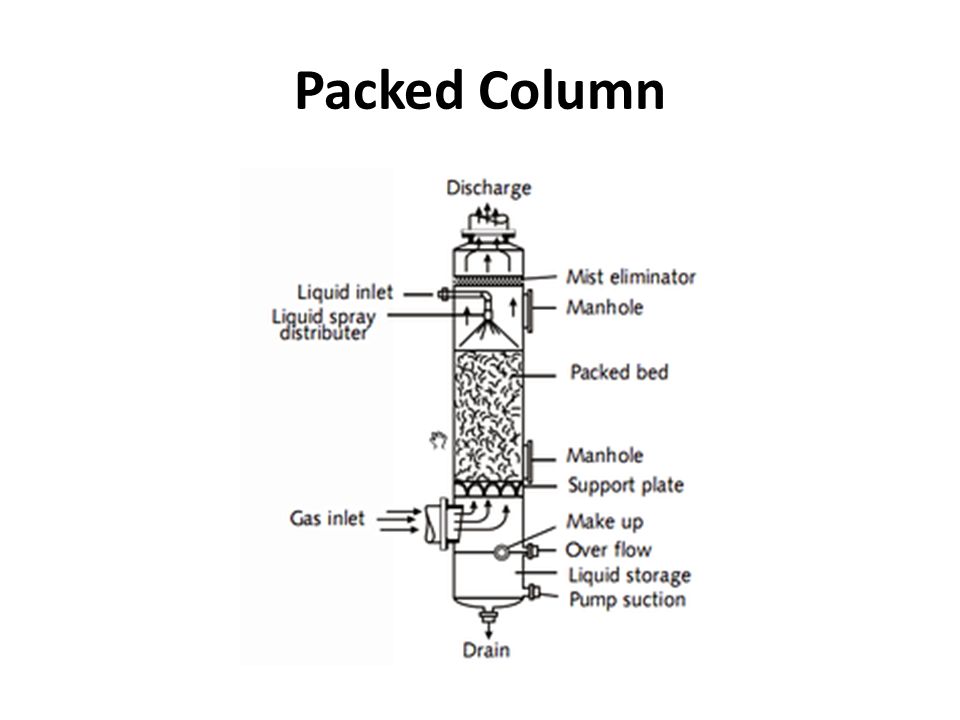

The gas liquid contact in a packed bed column is continuous not stage-wise as in a plate column. The packed column used for the separation of distillation is a vertical cylindrical vessel containing an appropriate packing bed supported and irrigated by the liquid flowing through a particular distributor. Choose an operating pressure 3.

Define product specifications 2. Now that you know what a packed column is we can move into the uses of packed columns. Because of their efficiency wide operating range ease of maintenance and cost factors sieve and valve trays have replaced the once highly thought of bubble cap trays in many applications.

The recommended practice for packed column design is dependent on the purpose for which the design is required. Packing supports hold-downs liquid collectors and other internals are designed to accommodate the higher capacities of high performance packing. Choose appropriate VLE data 4.

Packed columns are more suitablefor handling foaming system. In any column system packings can give an optimum performance only when complemented with appropriately designed tower distributors collectors supports and other column internals for optimum liquid vapour distribution to the packed beds. An INTALOX Packed Tower Systems design combines well-matched high performance packing and state-of-the-art liquid and vapor distribution to create predictable and reliable separation column performance.

For corrosive liquids a packed column will usually be cheaper than the equivalentplatecolumn packing should alwaysbe considered for small diameter columns say less than 06 m where plates would be difficult to install and expensive. Flanged columns Packings and internals are instal- led through the column flange. Uneven distribution may cause local variations in the liquidgas ratio localized pinch conditions and reduced vaporliquid contact.

Which includes column internals selection and sizing. Designing a packed dividing wall column for. 1 PANTAN certified according to ISO 90012015 for Designing and Manufacturing of Process Vessel Internals.

Perform tower sizing and tray hydraulics 8. Select a tray efficiency 6. Select appropriate tower internals 7.

Of Process Equipment Design Distillation Column Selection Sizing and Troubleshooting ENGINEERING DESIGN GUIDELINES Page 5 of 103. Download Table Unit Prices of Structured Packing Packed Column Internals and Sieve Trays from publication. Model 883 Structured Packing Bed LimiterLiquid Distributor Support For all column diameters with structured Construction Details Design Options packing Supports tubular channel or trough Standard construction is to have the Jack screws for diameters under type liquid distributors Model 883 bed limiter rest directly 36 in.

Your column and internals Sulzer Chemtech will verify with you the overall column height a nd the man-hole inside diameter. Welded vessel columns Packing and segmental internals are installed through manholes. The liquid flows down the column over the packing surface and the gas or vapor counter-currently up the column.

Advantages of packed column. These internals include vapor and liquid feed distributors packing support and hold down plates entrainment separators and liquid draw-off trays. Packed columns are called.

Packed columns are shorter than trayed columns. The most important aspects of packed-column internals and their design are outlined in the following paragraphs. Internals for packed columns.

Calculate the number of theoretical trays 5. KLM Technology Group Practical Engineering. The bed height is determined by the packing mass transfers capacity and constrained are governed by allowable pressure drop and the overall column height.

Number and size of the holes are design parameters. Columns packed with either random or structured packing must also include several additional key internal components that are necessary for the packing to function. Packed Columns Packed columns are used for distillation gas absorption and liquid-liquid extraction.

Koch-Glitschs dedication to provide state-of-the-art mass transfer equip- ment is demonstrated in a complete line of packed tower internals devel- oped through extensive testing and years of experience with mass transfer equipment such asINTALOXHigh Performance Distribution Systems. D A rough column sizing is usually all that is needed for initial flowsheeting studies. 340 14 Examples for the design of packed columns Yo mYXXo-Y0 14-13 Yu mYXXu-Yu 14-14 The corresponding equations for the liquid phase are xu 1 mYX 1 mYX Yo Yu 14-16 14-17 In a rectification process as illustrated in Fig.

Packed-tower efficiency and turndown are strongly dependent on the quality of initial liquid distribution.

Packed Tower An Overview Sciencedirect Topics

Packed Tower An Overview Sciencedirect Topics

Column Internals Saiptech Co Ltd

Volume Xxxi Column Internals Boardman Llc

High Peformance Internals Boost Tower Capacities China Packed Tower Technology Column Internals Made In China Com

Packed Tower Mass Transfer Equipment For Gas And Liquid Separating

0 comments

Post a Comment